- Home Page

- Company Profile

-

Our Products

- GRC Screen

- Columns & Capitals

- GRC Moulding

- Planters & Landscapes

- GRC Cladding

- GRC Fins

- GRC Noise Barrier

- GRC Replacing RCC

- GRC Products

- Industrial Everest GRC Projects

- GRC Baluster

- Exterior and Interior Decoration Lightweight GRC Brackets

- Glass Reinforced Concrete (GRC) Cornice For Interior and Exterior Decoration

- GRC Cladding

- GRC Column & Capital

- Weather-resistant GRC Cornice For Architectural Decoration

- GRC Dome

- Astetic Look High Strength GRC Gardening Benches and Pillars

- Everest GRC Jali

- Industrial GRC Molding

- Industrial GRC Planter

- Industrial GRC Production

- Decorative Lightweight GRC Texture Cladding

- GRC Screen

- GRC Windows And Screens

- Everest Decorative GRC Planters

- Design Panel GRC

- GRC Architectural Products

- GRC Bracket

- GRC Columns

- GRC Elevation

- GRC Grill

- GRC Pillars

- GRC Sun Sheds

- GRC Gazebo

- GRC Architectural Cladding

- Building GRC Jali

- GRC Lamp Posts

- Industrial GRC Balusters

- GRC Panel

- GRC Column Capitals

- GRC Dry Wall Cladding

- Lightweight, Aesthetic Finish GRC Cladding

- GRC 3D Design Project

- GRC Articles

- Industrial Everest GRC Baluster

- Decorative Designer GRC Brackets

- Industrial GRC Brick Wall Cladding

- GRC Brick Wall

- GRC Column & Capital

- Grc Cornice For Both Exterior and Interior Architectural Applications

- Weather-resistant, Lightweight GRC Customize Screen

- GRC Decorative Articles

- GRC Decorative Screen & Articles

- Platform GRC Decorative Screen

- Industrial GRC Dome

- Smooth Finish Architectural Grade Freestanding GRC Gardening Benches

- Industrial Everest GRC Jali

- Industrial Building GRC Molding

- Industrial Everest GRC Planters

- GRC Prestigious Projects

- Industrial Everest GRC Production

- Industrial GRC Screen

- Rectangular Shape GRC Texture Wall and Facade Cladding

- 3D Design Service

- Decorative Articles

- Wall Bricks

- GRC Prestigious Projects

- GRC Gardening Products

- FRP Roofing Products

- Prefabricated Structures

- Industrial Security Cabin

- Workman Colony

- Site Office

- Modular Cabins

- Toilet Block

- Vender Booth

- Telephone Booth

- Multi Store Labour Colony

- Bunk House

- Mobile Toilet

- Modular Toilet

- Porta Cabin

- Vending Booth

- Weighbridge Cabin

- Bunk House for Construction Site Office

- Air Conditioned Bunk House

- Bunk House for Apartment Site Office

- Bunk House For Gas Pipe Line Site

- Bunk House for Factory Site Office

- PHARMA CLEAN ROOM

- HOSPITAL BUILDING

- G Plus 1 Colony Prefabricated

- INSULATED STORAGE BUILDING

- Project Office

- WEEKEND HOMES (1-2-3 BHK)

- Project Executed

- Industrial Security Cabin

- Industrial COLD STORAGE ROOMS

- RELOCATABLE SITE OFFICE BUILDING

- Shift Shelter

- FRP Pultruded Structural Shapes

- Industrial Relocatable Site Office

- Project Office

- Industrial Factory Building

- SGB Project

- Public Hospital Building

- Fabricated Insulated Storage Building

- Industrial Lift & Shift Shelter

- Prefab Security Cabin

- Industrial Staff Quarters

- Weekend Home

- Workman Colony

- Staff Quarters

- Pharma Clean Room

- Industrial Insulated Storage Building

- Factory Building Office

- Industrial Relocatable Site Office Building

- Industrial Hospital Building

- Workmen Colony

- Lift & Shift Shelters

- Weekend Homes (123 BHK)

- Security Cabin

- Porta Toilets

- Vending Shop

- Portable Office Cabin

- Ventilating Systems

- Steel Turbo Roof Ventilating Systems

- Turbo Roof Ventilator

- Turbo Air Ventilator With Base Plate

- Industrial Roof Air Ventilator

- Streamline Ventilator

- Turbo Ventilator

- Polycarbonate Base Plate

- Ridge Ventilator

- Turbo Roof Ventilating System

- Roof Ventilator System

- SS Turbo Roof Ventilating System

- Mechanical Ridge Ventilator

- Prefabricated Roof Ventilator System

- PUF Panel

- UPVC Sheet

- Corrugated Panel

- Embossed Panel

- Roofing Sandwich PUF Panel

- Puf Panel Sheet

- Dwelling PPGI PUF Panel

- Sandwich Panel

- PUF Insulated Panel

- Sandwich PUF Panel

- Polyurethane Panel

- Coldroom Sandwich PUF Panel

- PUF Insulated Cement Sheet Wall Panel

- PUF Insulated Roof Panel

- PUF Insulated Wall Panel

- PUF Sandwich Panel

- Painted PUF Insulated Panel

- Coated PUF Insulated Wall Panel

- Color Coated PUF Insulated Cement Sheet Wall Panel

- Prestigious Projects

- TGB Surat

- Fusion Resturant Rajkot

- Shalimar Grand Lucknow

- Rajhans Zion Surat

- Pacafica Vadodara

- Voora Villa 96 Chennai

- Brahma Kumaris Bangalore

- Shalimar KSMB Lucknow

- BAPS Ahmedabad

- 9 Square Rajkot

- A R Dream Udaipur

- Central Bus Stop Vadodara

- Rajhans Feradio, Surat

- Samir Sethi Vadodara

- Shalimar Gallant Lucknow

- Shine Plaza Vadodara

- Swaar Sangini Surat

- Taiba Masjid Surat

- Talasan Ambaji

- Thaper College Chandigarh

- Trif (TATA) Nagpur

- Harish Patel Anand

- Eagle House Rajkot

- FRP Panels

- FRP Sheets

- Gutter Products

- GRP Products

- Decorative Premium Grade GRC Texture Cladding For Construction, Facade

- High Strength Grc Cladding For Facade Decoration And Building Protection

- GRP Panel

- GRC Screen

- Industrial Decorative GRC Brick Wall

- White GRC Production

- Everest Decorative GRC Brick Wall Cladding

- Galvalume Roofing Sheet

- GRC Prestigious Projects For Construction

- Weather-resistant Designer GRC Brackets For Office, Home, Hotels

- Decorative GRC Baluster

- White GRC Planter

- Industrial Building GRC Molding

- Everest GRC Articles

- Construction GRC Jali

- GRC 3D Design

- Everest GRC Projects

- Durable and Weather-resistant Glass Reinforced Concrete (GRC) Gardening Products

- Everest GRC Dome

- GRC Decorative Screen

- Industrial Decorative GRC Decorative Screen & Articles

- Everest GRC Decorative Articles

- Decorative Glass Fiber Reinforced Concrete (GRC) Customize Screen

- Lightweight Glass Reinforced Concrete (GRC) Cornice

- Designer GRC Column & Capital

- Doors

- Auto Mobile Sector

- Cladding Panels

- SMC Box

- GRP Pipe Fittings

- SMC Sheet

- Construction Material

- FRP Prefabricated Structure

- Exterior GRC Production

- FRP GRC Screen

- Building GRC Baluster

- Exterior GRC Dome

- FRP GRC Molding

- Customizable GRC Column & Capital

- GRC 3D Design Architectural Panel

- Industrial Everest GRC Articles

- Smooth Finish White Color Interior Exterior Decorative GRC Brackets

- Exterior GRC Brick Wall Cladding

- Architectural Textured/ Matte Finish Fire Resistant GRC Exterior and Interior Cladding

- Premium Grade Attractive Look GRC Customize Screen Suitable For Decorative Purposes Only

- Decorative GRC Decorative Articles

- Everest GRC Decorative Screen & Articles

- Premium GRC Decorative Screen

- Decorative GRC Planter

- Industrial Everest FRP GRC Prestigious Projects

- Air Conditioned Bunk House For Construction Site

- Bunk House For House Security Room

- Durable Weighbridge Cabin for Normal Working Conditions

- PUF Insulated Cabins

- Cold Storage Room

- Polycarbonate Multiwall Sheet

- Polycarbonate Sheet

- Extra Links

- Contact Us

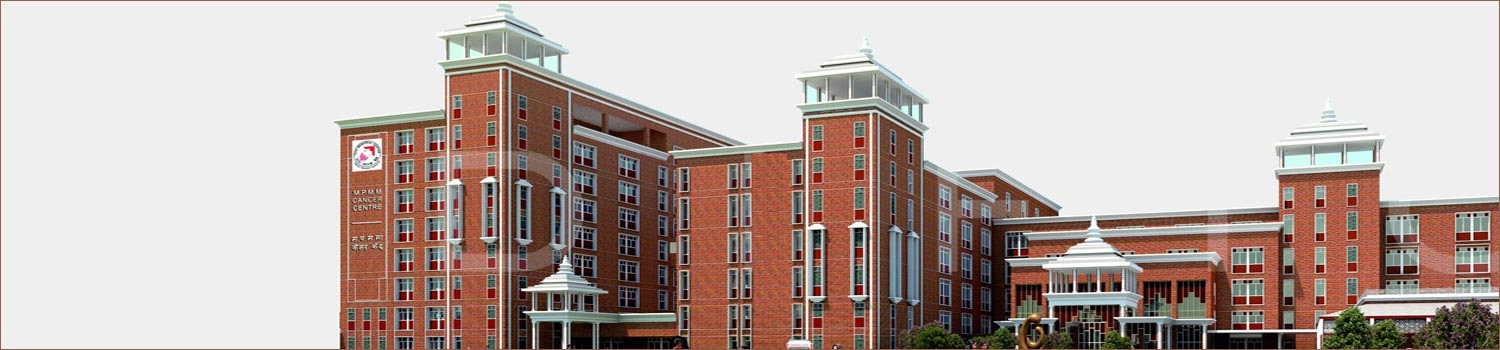

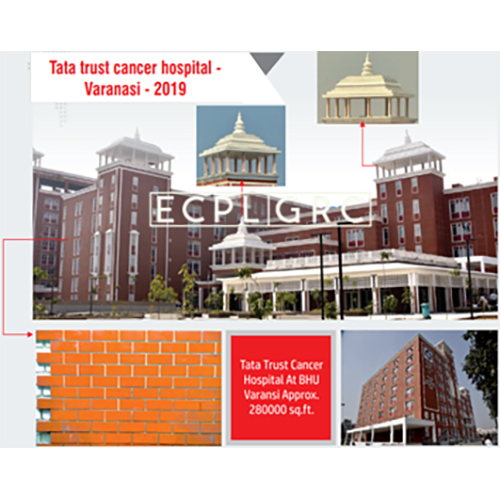

Industrial GRC Prestigious Projects

Product Details:

X

Industrial GRC Prestigious Projects Price And Quantity

- INR

- 100 Square Foot

Industrial GRC Prestigious Projects Trade Information

- 10000 Square Foot Per Day

- 1 Week

Product Description

Wide range of products are widely admired for their high strength and top quality. ECPL is known for its strong technological capability, scalability and adaptability that are required to meet the constantly changing prerequisites of our clients.

Leveraging its industry expertise, stringent standards and driven workforce, ECPL delivers unmatched services & best quality products. This has made Everest Composites an innovative pioneer and leader in the industry.

Features

- 500+ Corporate Clients

- 25+ years of experience in the Composite Industry

- Best Quality Products

- Reliable & Secure Services

- Eco Friendly Process

- Customer Centric

Advanced Design Flexibility

Industrial GRC Prestigious Projects leverage the unique properties of GRC to deliver intricate designs and complex shapes, suitable for creative architectural demands. Whether you require panels, cladding, or molded elements, customization is available for all project sizes. This material's adaptability ensures no compromise on aesthetics or structural requirements.

Sustainable and Lightweight Solutions

GRC is inherently environmentally friendly, using less raw material and energy than traditional concrete. Its lightweight nature reduces structural loads and handling costs during installation. Despite being lighter, GRC components maintain high strength and longevity, making them a responsible and efficient choice for modern industrial architecture.

Hassle-Free Installation and Maintenance

With an on-site installation facility available, these GRC projects offer convenience and efficiency for both large and small-scale projects. Thanks to the material's durability and low water absorption, routine maintenance is minimal. The robust composition withstands aggressive environments, ensuring long-term performance with little upkeep.

FAQ's of Industrial GRC Prestigious Projects:

Q: How is on-site installation managed for Industrial GRC Prestigious Projects?

A: On-site installation is handled by experienced professionals who ensure that each GRC component is fitted precisely according to project specifications. Our technical team collaborates with project managers to complete installation safely and efficiently, regardless of project complexity or location.Q: What makes GRC suitable for both internal and external applications?

A: GRC's high flexural and tensile strength, along with excellent weather and fire resistance, make it equally effective for both indoor and outdoor architectural applications. Its low water absorption and non-combustible nature further enhance its applicability across a wide range of environments.Q: When is it beneficial to use GRC elements in industrial architectural projects?

A: GRC is particularly advantageous when projects require lightweight, durable, and customizable components with sophisticated design features. It is ideal for aggressive environments where minimal maintenance and high longevity are desired, such as in industrial facades, cladding, or decorative architectural details.Q: Where can Industrial GRC Prestigious Projects be applied?

A: These GRC solutions are adaptable to diverse architectural environments including factories, commercial spaces, institutional buildings, and infrastructure projects across India and international locations. Their flexibility makes them suitable for both large-scale industrial and more specialized prestigious projects.Q: What customization options are available for GRC products?

A: We offer extensive customization in terms of shapes (panels, cladding, molded elements), thickness, colors (natural grey or pigmented), and surface finish (smooth, textured, or custom). These options allow our clients to achieve specific design intents and functional requirements for projects of any size.Q: How does the durability of GRC compare to traditional concrete in harsh environments?

A: GRC surpasses traditional concrete in durability, offering higher resistance to weather, fire, and aggressive environmental factors. Its glassfiber reinforcement provides superior flexural and tensile strength, ensuring a longer service life with minimal signs of wear even in challenging conditions.Q: What are the environmental benefits of using GRC for industrial projects?

A: GRC is an eco-friendly material as it consumes fewer natural resources and produces less waste compared to conventional concrete. Its manufacturing process and longevity reduce the environmental footprint, making it a sustainable solution for modern industrial architecture.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'GRC Prestigious Projects' category

|

EVEREST COMPOSITES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |